VALUE WAREHOUSING

Revolutionising Stock Management: The Power of a Warehouse Management System (WMS)

From manual struggles to strategic solutions: A comprehensive look at stock management in today’s business landscape

Consider

this

For many businesses operating without a Warehouse Management System (WMS), manual spreadsheets remain a common, though inefficient, approach to managing inventory. While they may seem practical and cost effective in the early stages, as operations grow, these spreadsheets tend to multiply, becoming cumbersome and difficult to manage.

Relying on manual processes brings a range of challenges that can severely impact the efficiency, productivity, and profitability of warehouse operations.

These challenges include:

Human Intervention and Error: Dependence on manual handling increases the risk of human error. Mistakes can affect the accuracy of stock records and transactions, often leading to costly oversights. Investigations to rectify these errors further also have a ripple effect on inefficiencies and cost.

Tedious and Time-Consuming Procedures: Labour-intensive workflows slow down warehouse operations, making processes inefficient and draining resources.

Reactive Management: Unlike a WMS, traditional systems lack proactive tools, limiting opportunities for strategic decision-making and leading to reactive management.

High Resource Demand: Managing stock by hand requires significant time and manpower, which drives up operational costs.

Lower Inventory Accuracy: Without automated verification, inaccuracies in inventory tracking become more common, reducing overall stock control and visibility. Item lacks or incorrect items picked on orders will become more prevalent risking service level agreements with customers.

Increased Risk of Stock Losses: Tracking stock without automation often leads to losses, especially through expired or obsolete inventory, impacting profitability. Conversely, the risk of issuing expired stock exists (such as food items, medicine, etc.) and could put vendors at risk from consumer claims.

Slower Turnaround Times: Non-automated workflows delay stock availability, order processing, and fulfilment, impacting customer satisfaction.

Suboptimal Solutions: Traditional allocation and rotation of stock lead to inefficient warehouse management and limit optimal outcomes.

Limited Visibility: Tracking stock movement without automated systems can be cumbersome, making it difficult to monitor inventory efficiently at a batch or receipt level.

From the increased likelihood of human error, to the strain on resources; and slower turnaround times, these challenges introduce significant complexity into daily operations, impacting all aspects from stock management accuracy to strategic decision-making. As businesses expand, these issues only become more pronounced, underscoring the limitations of manual systems.

The

solution

is clear

Implementing a WMS is crucial for overcoming the challenges businesses encounter when lacking an efficient stock management system. By partnering with experienced professionals like Value Warehousing, you’ll benefit from a robust WMS solution that addresses these challenges, providing a range of advantages that streamline operations and enhance overall efficiency.

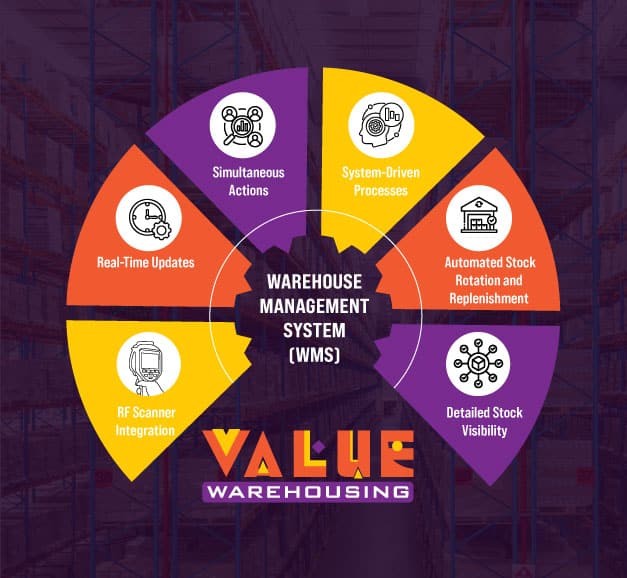

The benefits of utilising a Warehouse Management System (WMS) to effectively manage your inventory:

Detailed Stock Visibility: A WMS provides comprehensive visibility of stock from receipt to dispatch, including efficient handling of returns, ensuring complete visibility at every stage of the process.

Product Characteristics Management: The WMS easily manages stock based on key attributes such as product code, different SKU levels, product type, production date, expiry date, shelf life; and batch number, allowing for precise control of inventory.

RF Scanner Integration: Utilising RF scanners for multiple functions, including receiving, picking, cycle counting, and stock taking, increases efficiency and accuracy.

Real-Time Updates: Benefit from real-time stock and location updates as inventory is physically processed, ensuring accurate, up-to-the-minute information across all warehouse operations.

Simultaneous Actions: Achieve seamless efficiency with simultaneous real-time stock status updates, system-to-physical actions, and automated processes driven by pre-configured rules.

Auditable Stock Movements: Gain full transparency with auditable records of inbound, outbound, and general inventory movements, ensuring traceability and accountability.

System-Driven Processes: A WMS automates essential tasks, from put-away to storage, ABC classification, stock allocation, replenishment, expiry management, and more, reducing the need for manual input.

Automated Stock Rotation and Replenishment: A WMS automates critical tasks like stock rotation, replenishment to pick faces, and ABC placement, as well as the automatic blocking of expired items, ensuring optimal stock health and availability.

Stock Condition Management: A WMS systematically segregates stock based on physical conditions, offering visibility into categories such as “Good for Sale,” “Quarantined,” “Blocked,” and “Expired/Near Expiry,” so you can manage stock health effectively.

Failure

to act

Companies struggling with manual stock management systems will inevitably encounter numerous challenges that hinder operational efficiency and accuracy. Considering these obstacles, outsourcing warehousing solutions to experienced professionals, like Value Warehousing becomes crucial for businesses seeking to improve the accuracy, efficiency, and overall effectiveness of their inventory management processes. Partner with Value Warehousing to optimise your stock management.